| product material | 1. Toggle switch | Material | ||

| 2.Plastic | PPA/PA10T/PA66 | |||

| 3.Contact sheet | brass | |||

| 4.Button | POM | |||

| 5. Pin | Brass silver plated/brass gold plated | |||

| 6.Spring | SUS304 | |||

| Electrical properties | Operating temperature range | -10℃±60℃ | ||

| Maximum rating (resistive load) | 6A 125V AC | |||

| Minimum rating (resistive load) | 3A 250V AC | |||

| Operating force | 450gf±150gf | |||

| Withstand voltage | 500VAC | |||

| Insulation resistance | 100MΩ | |||

| Contact resistance (initial/after life) | 30MΩ | |||

| Durability | No load life | 10000 times | ||

| Load life (maximum rated load) | 10000 times | |||

| Environmental resistance | Cold resistance | -40±3°C/96h | ||

| Heat resistance | 70±2°C/48h | |||

| Moisture resistance | 40±2°90 to 95% relative humidity 96/h | |||

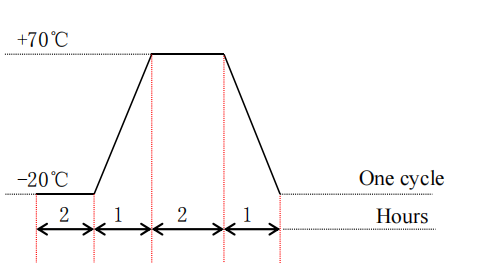

| Temperature alternating test | ||||

| For example, in the environment shown in the icon, after 5 cycles, place it in a normal environment and test after 30 minutes. | No signs of damage to mechanical or electrical performance | |||

| Solderability test |

|

More than 95% of the surface of the immersed part will be covered with tin | ||

| The top of the terminal is immersed in the solder pool 2mm deep, the temperature is 240±5°C, and the time is 3 seconds. Lead-free tin test: composition: tin 96.5%, copper 3%, silver 0.5% | ||||

| Solder resistance test | When hand welding, the temperature needs to be controlled at 360±10℃ and the time is 3±0.5 seconds, but abnormal pressure cannot be applied to the terminals. Lead-free tin test: Ingredients: 96.5% tin, 3% copper, 0.5% silver | The body has no deformation and can meet the mechanical and electrical performance | ||

0769-82056828

0769-82056828

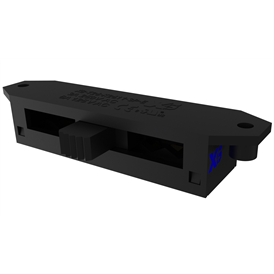

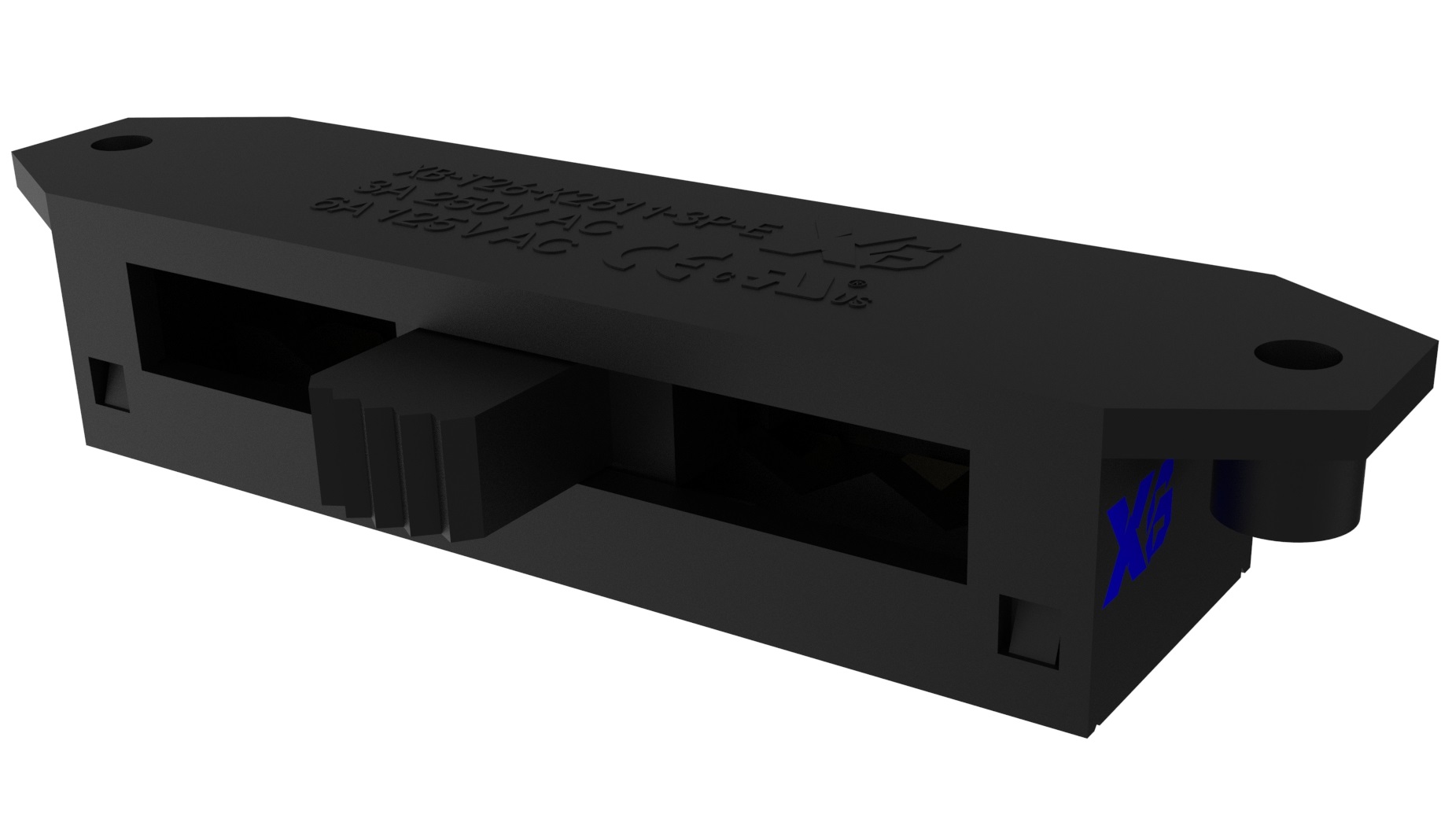

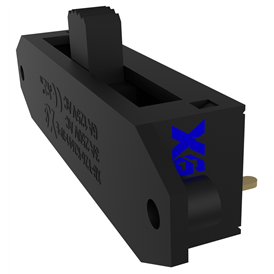

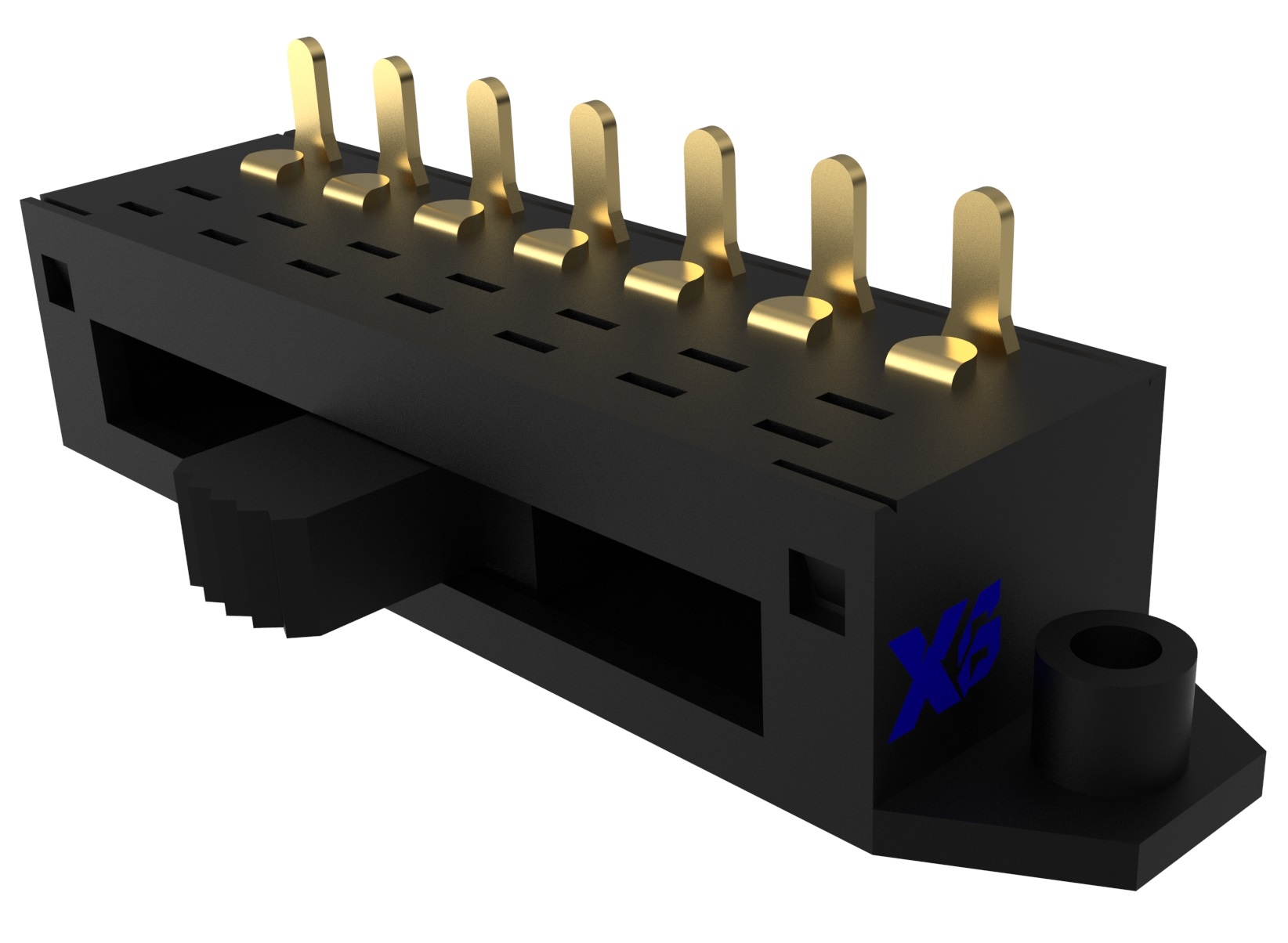

XB-T26-K2611-7P-E

XB-T26-K2611-7P-E 3D

3D Drawings

Drawings

ABS English

ABS English

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website