Overview and application analysis of blade connector spacing selection technology

Publisher: Administrator Date:2025-03-11

I. Blade Connector Overview

Blade connectors are electromechanical components that achieve electrical connections through elastic contact between metal blades and sockets. Widely used in power distribution, signal transmission, and equipment interconnection, their core advantages include compact design, easy insertion/removal, and cost-effectiveness. As electronic devices trend toward miniaturization, connector pitch selection has become critical for optimizing system design.

II. Working Principle & Technical Characteristics

-

Contact Mechanism

-

Elastic Contact Principle: Relies on socket spring preload deformation to generate contact force (typical range: 5-20N).

-

Multi-Point Contact Design: Blades feature凹凸textures to form 3-5 independent contact points.

-

Contact Resistance Model:Rc=A⋅N⋅Fρ, whereρ=material resistivity,A=contact area,N=contact points,F=contact force.

-

Electrical Characteristics

|

Parameter

|

Typical Range

|

Influencing Factors

|

|

Rated Current

|

5-50A

|

Conductor cross-section, temperature rise

|

|

Contact Resistance

|

1-20mΩ

|

Surface finish, contact pressure

|

|

Insulation Resistance

|

>100MΩ @500VDC

|

Material dielectric strength, humidity

|

|

Withstanding Voltage

|

250-1500VAC

|

Creepage distance, material CTI value

|

-

Mechanical Characteristics

-

Mating cycles: 500-10,000 (gold-plated contacts: up to 50,000)

-

Insertion force: 0.5-5N/contact

-

Retention force: >15N axial pull

III. Critical Pitch Parameter Analysis

-

Pitch Definition System

-

Center Pitch: Distance between adjacent contact centers (e.g., 2.54mm/1.27mm/0.8mm).

-

Pole Spacing: Shortest surface distance between adjacent live conductors.

-

Safety Spacing: Complies with IEC 60664-1 insulation coordination requirements.

-

Mainstream Pitch Specifications Comparison

|

Pitch (mm)

|

Current Rating

|

Typical Applications

|

Wiring Density (pins/cm)

|

|

5.08

|

30-50A

|

Industrial power distribution

|

2.0

|

|

3.96

|

15-30A

|

Modular UPS systems

|

2.5

|

|

2.54

|

5-15A

|

PCB inter-board connections

|

3.9

|

|

1.27

|

1-5A

|

High-density backplane connectors

|

7.9

|

|

0.8

|

<1A

|

Miniaturized consumer electronics

|

12.5

|

、

-

-

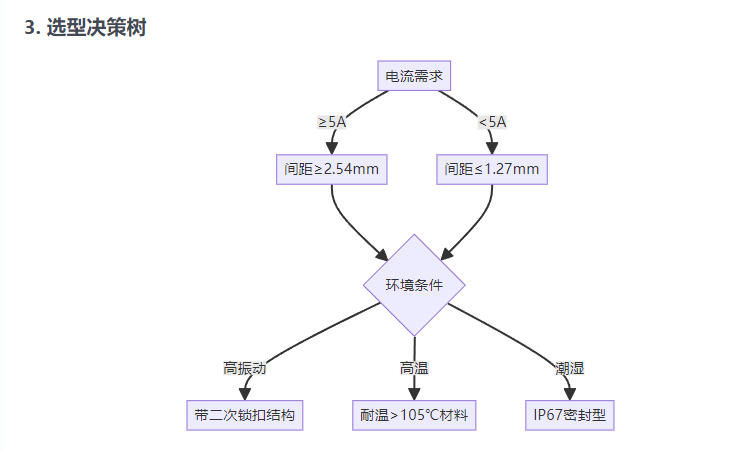

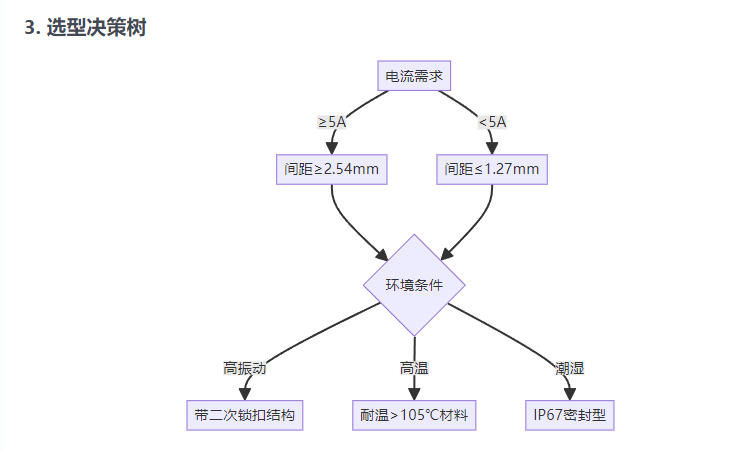

Pitch Selection Technical Considerations

-

Current capacity: 5.08mm pitch supports 50A @20°C

-

Insulation reliability: 1.27mm pitch requires CTI ≥250V

-

EMC: Smaller pitches increase crosstalk (e.g., <-40dB @1GHz for 2.54mm)

-

Manufacturing: <0.5mm pitch requires precision stamping + laser trimming

IV. Type Classification & Selection Strategy

-

Functional Classification

-

Power Type: Thick copper alloy blades (0.3-0.8mm), pitch ≥2.54mm

-

Signal Type: Gold-plated phosphor bronze, supports >10Gbps speeds

-

Hybrid Type: Integrated power/signal contacts

-

Mounting Method Classification

|

Type

|

Structural Feature

|

Applications

|

|

Vertical

|

90° vertical mounting

|

Standard PCBs

|

|

Right-Angle

|

L-shaped bend

|

Space-constrained devices

|

|

SMT

|

Surface-mount soldering

|

Automated production

|

|

Crimp

|

IDC insulation displacement

|

Rapid cable assembly

|

V. Typical Applications

-

Industrial Control Systems

-

5.08mm pitch connectors for 24VDC/10A power (e.g., Siemens S7-1200 PLC interfaces).

-

New Energy Vehicles

-

8-12mm HV connectors for 600V/150A, dual-lock design with HVIL.

-

5G Equipment

-

0.8mm backplane connectors (120pins/100mm), impedance control ±10%, <0.5dB loss @28GHz.

-

Medical Devices

-

1.27mm medical-grade connectors (ISO 13485 certified, sterilization-resistant).

VI. Advanced Technology Trends

-

High density: Molex MicroBlade (0.4mm pitch)

-

Smart connectors: TE Connectivity’s sensor-integrated Smart Blade

-

Material innovation: Graphene composite reduces contact resistance by 40%

-

Manufacturing: 3D SLM-printed contacts

VII. Reliability Validation Methods

-

Current cycling: 1,000 cycles (0-rated current), ΔR <10%

-

Mixed flowing gas test: ≤20% contact resistance change after 4 weeks

-

Mechanical shock: 50G@11ms half-sine wave, zero failure

-

FEA: Simulates structural deformation under 500N misinsertion force

VIII. Selection Checklist

☑ Verify max operating/pulse current

☑ Evaluate ambient temperature & cooling

☑ Measure installation space/height limits

☑ Confirm IP rating requirements

☑ Check PCB layout & trace capacity

☑ Validate mating cycles & maintenance

☑ Calculate TCO (including tooling)

0769-82056828

0769-82056828

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website