| Product ID | Product Image | Product Description | Product Code | Production status | Shipping Cycle | Gross item weight | MPQ | MOQ | Production in transit | Competitive purchases | Operation |

XB-SATA-F22-35SSERIES  3D 3D

Drawings Drawings |

|

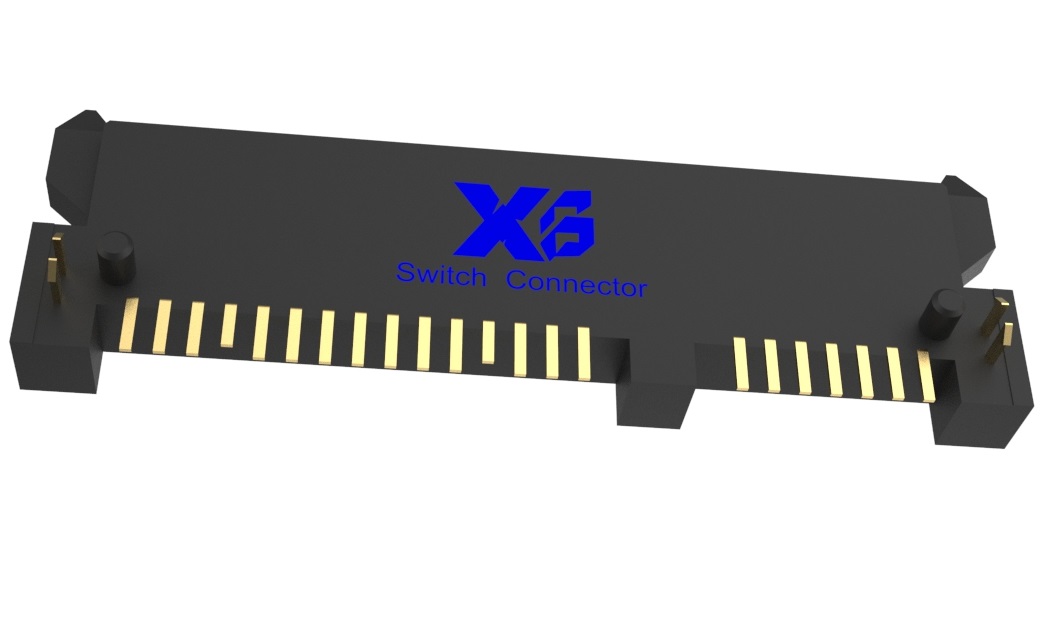

40.43 * 12.87 * 3.55mm SATA connector 7PIN+15PIN R/A DIP reverse/SATA interface 7PIN+15PIN/SATA socket/SATA socket 7+15P female/hard drive SATA connector/computer SATA socket 7+15P R/A DIP reverse | Sata connector | Normal | 1-2 weeks | 0.45g | 1000 PCS/disk | 30000 PCS/disk | 100000 |  Compatible Xibang |

|

XB-SATA-F22-35SSERIES-X  3D 3D

Drawings Drawings |

|

40.43x12.87x3.55mm/computer SATA connector 7PIN+15PIN R/A DIP reverse/hard drive SATA interface 7PIN+15PIN/SATA socket/SATA socket 7+15P female socket/hard drive SATA interface/computer SATA female socket 7+15P R/A DIP reverse | Sata connector | Normal | 1-2 weeks | 0.45g | 1000 PCS/disk | 30000 PCS/disk | 100000 |  Compatible Xibang |

| product material | 1.Sata connector | Material | ||

| 2.Contact | copper alloy | |||

| 3.Plastic | LCP/UL94V-0 | |||

| 4.Terminal | copper alloy | |||

| 5. Shell | Brass silver plated | |||

| Electrical properties | Rated current | 1.5A | ||

| Rated voltage | 12VAC | |||

| Insertion and extraction force | 10N-45N | |||

| Withstand voltage | 500VAC | |||

| Insulation resistance | 100MΩ | |||

| Contact resistance (initial/after life) | 30MΩ | |||

| Durability | No load life | 5000 times | ||

| Load life (maximum rated load) | 5000 times | |||

| Environmental resistance | Cold resistance | -40±2℃ for 48h | ||

| Heat resistance | 85±2℃ for 48h | |||

| Moisture resistance | 40±2℃, 90 to 95%RH for 48h | |||

| Weldability | Immerse the soldering terminals into velvet tin at 235°C for 3±0.5s with a minimum immersion depth of 2mm. | More than 95% of the surface of the tin-immersed part must be well dipped in tin | ||

| Resistant to reflow heat | Preheating: 150°C~180°C 90±30s Heating 230°C 30±10s Heating peak 260°CMAX: 20s~40s | The appearance should be free of damage, the terminals should not be loose, and the plastic should not be deformed. | ||

0769-82056828

0769-82056828

XB-SATA-F22-35SSERIES

XB-SATA-F22-35SSERIES ABS English

ABS English

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website