| Product ID | Product Image | Product Description | Product Code | Production status | Shipping Cycle | Gross item weight | MPQ | MOQ | Production in transit | Competitive purchases | Operation |

XB-MRUSB-5B-D17  3D 3D

Drawings Drawings |

|

6.9 * 6 * 2.35mm flat port Micro2.0 connector/Micro2.0 USB interface/Micro2.0 socket/Micro2.0 USB socket connector 5PIN |  Compatible Xibang |

||||||||

XB-MRUSB-5B-D17-X  3D 3D

Drawings Drawings |

|

6.9 * 6 * 2.35mm flat port Micro2.0 connector/Micro2.0 USB interface/Micro2.0 socket/Micro2.0 USB socket connector 5PIN |  Compatible Xibang |

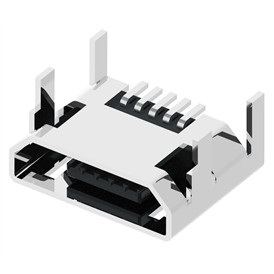

| Product material | 1.MICRO USB | material quality |

| 2. Contact terminal | yellow metal | |

| 3. Metal shell | Brass silver plated | |

| 4. Rubber shell shell | PBT UL94V-0 | |

| Product type features | Type of connector: | The mother end |

| direction: | right angle | |

| Connector system: | Cable to board | |

| Sealable: | yes | |

| Connector and terminal are terminated to: | printed circuit board | |

| Colour of glue core | Black / white | |

| Number of ports: | 1 | |

| End-connection features | Terminal terminal type: | Surface mount / plug-in |

| PCB termination method: | Surface mount / insertion | |

| Contact features | Terminal rated current (maximum value) (A): | 1A 12V AC |

| machine accessory | installation site: | Intermediate installation |

| PCB Installation fixed type: | Welding wire / welding plate | |

| Connector installation type: | Board installation | |

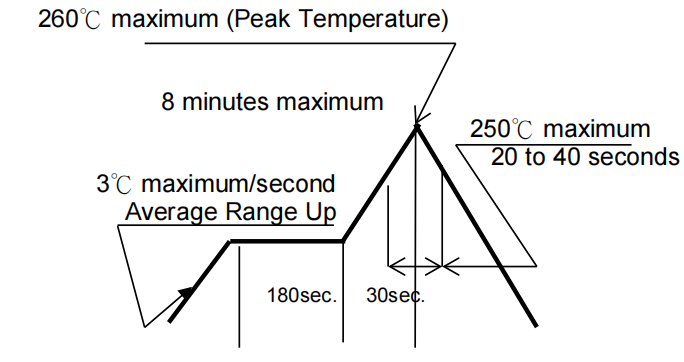

| service environment | Welding temperature (max.): | 260°C |

| preheat temperature | 150~200°C | |

| Plug-in period (max.): | 1500 | |

| Group temperature range: | -40°C±85°C | |

| Operation / application | Be able to pick up: | deny |

| Circuit application: | Power supply and signal | |

| Packaging characteristics | Packaging method (patch SMD): | Roll / package |

| Packaging method (plug-in DIP): | Plastic suction / packaging | |

| Welding experiment | Dip the terminal foot in the flux for 5 seconds, then immerse the terminal foot in a 245 ± 5℃ tin furnace for 3 ± 0.5 seconds | The tin attached area shall exceed 95% of the immersion surface area |

| Reflow welding and wave crest welding experiments | wave-soldering | The recommended solder temperature is 260℃ (500°F) for a maximum of 5 seconds |

| Hand welding | The 30W flipping iron is used to control the temperature at 350℃, and the welding time is about 5 seconds | |

| Back furnace welding | The maximum temperature of SMT backwelding furnace is 260℃ and the temperature is 260℃, the maximum time shall not exceed 10 seconds | |

|

|

||

0769-82056828

0769-82056828

XB-MRUSB-5B-D17

XB-MRUSB-5B-D17

ABS English

ABS English

Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Add me as a friend

Add me as a friend  Website

Website